Heat transfer decorating at up to 600 textiles per hour - with a single operator!

This is what the TURBOTRAN 6.1 is build for.

This unique heat transfer machine is all you need to lift textile heat transfer into a new dimension. Due to the high level of automation, this machine can handle every step of the decoration process on its own. As a result, the operator’s task can be trimmed to focus on feeding the machine with textiles. And even here the TURBOTRAN 6.1 assists you with laser guidance and our intuitive “in-and-out system”. As a result, the number of possible errors and risk of producing scrap is minimized.

Equipped with 2 transfer presses, an automatic transfer positioning, a peeling unit for the carrier material and an automatic outfeed, the TURBOTRAN 6.1 makes your production more efficient and more comfortable for the operator at the same time.

On top of that it can be customized with standard or membrane platens in any size you want, a quick-change system for such platens, different outfeed options and more.

From T-Shirts over sportswear to work wear, anything can be decorated. Same goes for your preferred type of transfer, which can be a water based, plastisol or digitally printed heat transfer.

You want to know more about this unique machine, just send us a message and we will set you up with all you need to increase your productivity.

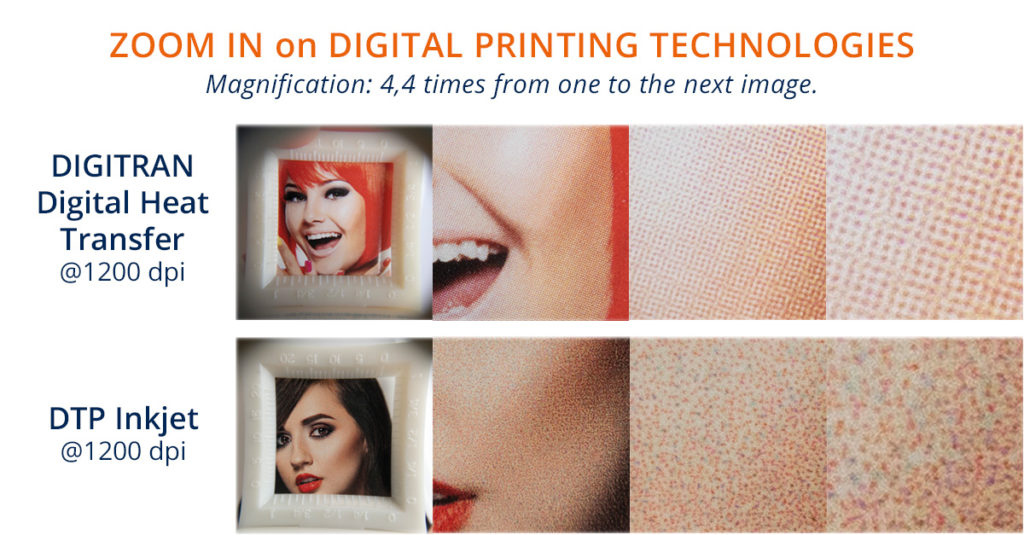

Would you think that 1200dpi and 1200dpi digital printing is the same? You probably would.

But actually no, not even close!

Especially when it comes to photo-realistic printing and skin tones the print quality must be on point. The confusing part is that even though both prints shown in the photo have a resolution of 1200 dpi, they are obviously not the same. But how does that come?

Why cosmetic tubes are perfect promotional products? Because they are compact, useful and give enough space for your message.

And we are here to get them printed, also in small quantities!

As a contract decorator who prints your tubes just in time and in almost any quantity, or as your partner for heat transfer machines as well as digital heat transfer decals, we have the perfect solution for you.

What you should know about the advantages of printing different names, languages, numbers and codes – in one run!

Starting with printing different names on promotional products over serialized special editions to a print run with every image being different. With digital heat transfers you can achieve all this. Without UV, without solvents and without stopping your heat transfer machine.

3 sides, 3 different photo-realistic images.

That is what a paper cube box can look like when you print it with DIGITRAN digital heat transfer technology.

Lip balm comes in pretty much just one shape, which makes the print is even more important for this type of packaging.

With digital heat transfers we ensure that your product will stand out!

Especially when it comes to multi-color designs there is close to none in the shelves. Simply because multi-color designs are difficult to print onto a small lip balm shell and the more colors there are, the more it costs.

To bring more diversity to this product we developed DIGITRAN digital heat transfer decals as well as DIGITRAN heat transfer equipment for it