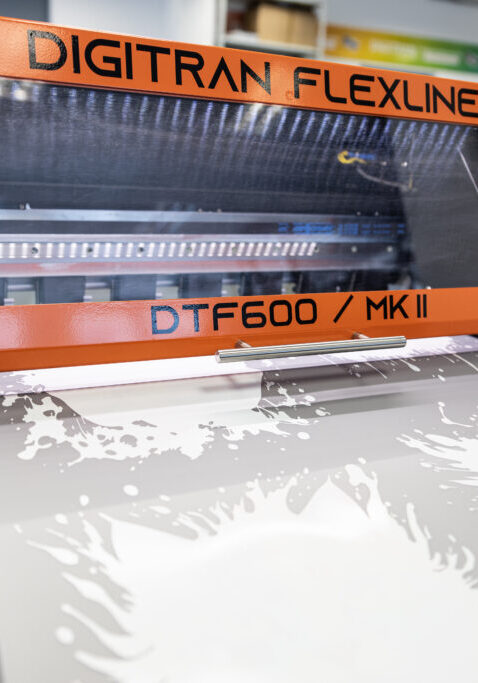

DTF Printer - DIGITRAN FlexLine DTF600 MK2

Our best Direct to Film (DTF) printer for digitally printed textile transfers

Features

OEKO-TEX water-based ink

Max. 720x2400dpi resolution

2 print head system

Color profiles for different applications

Printing, powder and drying in line

Highest color accuracy thanks to Color Management

White circulation pump and agitator

Automatic cleaning cycles

Efficient printing width of 600mm (24'')

Print at up to 14m²/hr.

4, 6 and 8-pass print modes

For various textiles and applications

Perfect stretch and washability

Dimensions approx. 1,4 x 2,5m

DIGITRAN FlexLine DTF600 Mark-2 - the next generation DTF printer.

This direct to film printer enables the fast and easy production of transfers for your textile printing business.

For this purpose, the digital printing press is expanded with the FlexFinish600 Mark2 powder and drying unit. Compared to the predecessor model, this has been designed as a longer version in order to enable more uniform drying.

What has remained the same is that the adhesive powder is sprinkled into the ink fully automatically. The subsequent shaking unit also completely removes any excess adhesive. Finally, the image is dried with a powerful IR unit and then wound up. Now it's simply a matter of removing the print images, cutting them to size if necessary, and sending them off or applying them yourself.

Thanks to its energy-saving design, the machine system can be operated entirely via regular power sockets.

The DTF printer for a fast, safe and easy production!

The DTF Printer

The digital printing machine from this Direct-to-Film (DTF) machine system is equipped with 2 robust EPSON i3200-A1 print heads of the latest generation. These can print in CMYK, a highly opaque white and a resolution of up to 720x2400dpi.

This means that even the finest elements and gradients can be reproduced. For clean quality, we use water-based, OEKO-TEX certified inks.

Automatic cleaning cycles and ink circulation ensure maximum durability of the print heads.

The printing machine is also designed for a maximum print width of 600 mm and can print suitable hot-peel or cold-peel films.

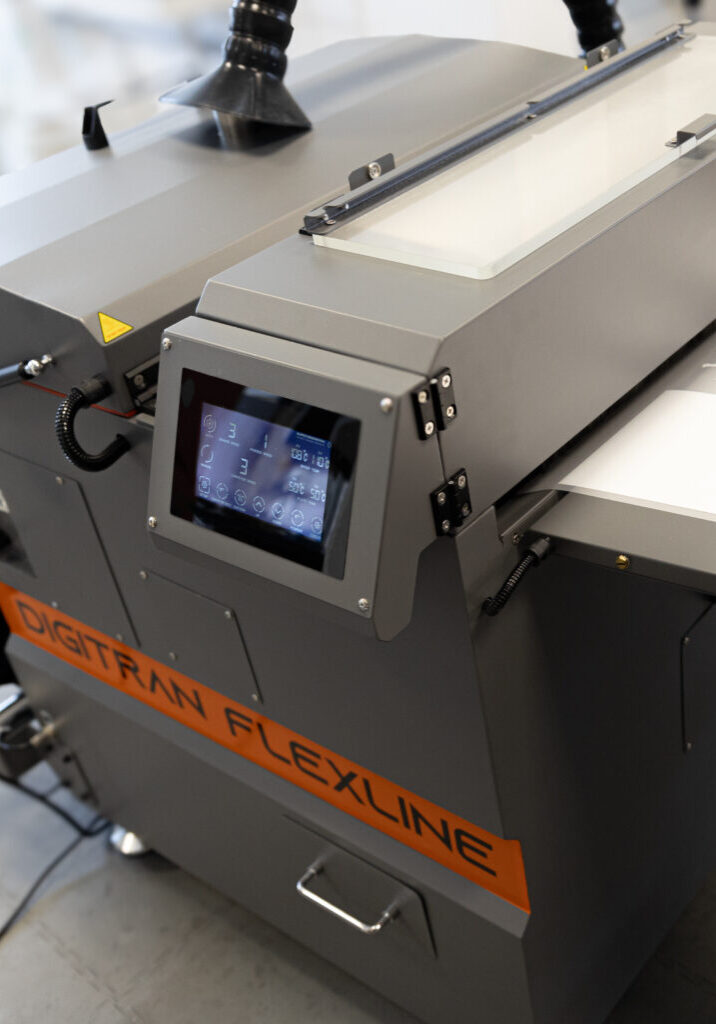

The powder machine

The FlexFinish600 MK-II powder unit is positioned in line with the printing machine and is responsible for finishing the transfer. The hot-melt powder is crushed with a rubberized squeegee and spread over the still wet print image. The excess adhesive powder is then tapped off in a controlled manner so that no residue remains on the unprinted film.

Then the image is dried and bonded to the adhesive using efficient IR drying. The drying channel is insulated to make this as energy-efficient as possible. Finally, a fan ensures that the finished printed image is cooled and can be wound up as a roll without sticking.

The powder unit is controlled via a compact touch display.

Perfect color management

We create our own color profiles for our printing systems so that you not only print beautifully, but also correctly.

For each print mode supplied with the machine, corresponding test images are printed and measured. These measurements are used to calibrate the machine and create an ICC profile so that the colors in the print match the colors in the file as closely as possible.

Whether black, colored or white, we have the right color profile for every substrate. In addition, you have various other options to adjust colors for your designs. From highlight white to the removal of white, black or individual colors to the simple, manual adjustment of individual colors, everything is possible.

Request Your Sample or Demo Now

And see the quality of the DIGITRAN FlexLine DTF600 MK2 for yourself.

DTF Printer from DIGITRAN

All machines are technically and functionally tested prior to shipping so that you receive a safe and reliable printing machine.

We can also take care of the installation for you and thus ensure a quick and uncomplicated start to DTF printing. And should something not work as expected, our service is there for you. Whether by phone, email or directly on site.

Consumables as well as wear and spare parts are also available from us. Whether ink, glue, foils, print heads, dampers or software, everything comes directly from our warehouse and is with you in the shortest possible time.

With us, you can expand your transfer production with a timely, digital solution. Perfect for smaller batch sizes, multi-color designs and short response times.

Why DTF (Direct To Foil/Film) Printing

DTF Textile Transfers - Perfect for small and medium batch sizes

In-Line DTF printers are the perfect solution when it comes to small and medium batch sizes. Since no make-ready is required for printing, any color, shape and size can be printed in a very short time. Our system also allows different white layer thicknesses to be printed. Thus, ink can be saved on a light textile and maximum ink coverage can be achieved on a dark ones.

The digitally printed transfers are characterized by outstanding color intensity. They can also be applied quickly and easily to cotton, polyester, 50/50 blends and various other materials. At the same time they are stretchable, colorfast and long-lasting.

Another advantage is that the transfers can be produced independently of the final application process. This means that they can be prepared for upcoming orders and called up for decoration as required. Screen printing, vinyl and digital transfers can thus be used in combination on any heat transfer press. Whether 100,000 single-color screen prints, plotted silver vinyl or digital photo prints.

Looking for transfers only?

Here, too, we can help you. We can supply you with transfers in all common DIN-A formats. Perfect for T-shirts, bags or hoodies as work, sports or leisure wear. Cotton, polyester as well as blends can be finished with these transfers. Furthermore, we offer different variations for light and dark textiles as well as recommended settings for your textiles.

Our digitally printed transfers are available in all quantities from 1 to 10,000 pieces and can be printed and shipped in just a few days. Just send us a short message with the intended quantity, size and application and we will send you back a non-binding offer.